Choosing the wrong plastic[^1] can ruin your product and brand. This costly mistake leads to leaks and degradation. Understanding the materials is the key to making a smart choice.

Choosing the right plastic[^1] involves matching the material's properties, like chemical resistance[^2] and durability[^3], with your product's formula and lifecycle. This ensures product integrity[^4], user safety[^5], and brand reputation. It's about performance first, then appearance.

I've been in this industry for a long time, and I've seen brands make the same mistakes over and over. They fall in love with a certain look without thinking about the science behind the material. This guide is here to change that. We will walk through everything you need to know to pick the perfect plastic[^1] for your product, saving you time, money, and a lot of headaches down the road. Let’s get started.

Why Do Plastic Materials Matter So Much in Cosmetic Packaging?

You might think all plastic[^1] is the same. This assumption can lead to costly packaging failures and damaged brand trust. Knowing the differences is critical for your product's success.

Plastic materials matter because they directly impact product stability, shelf life[^6], and the user experience. The wrong plastic[^1] can react with your formula, fail during shipping, or feel cheap to the customer, ultimately harming your brand's reputation.

The choice of plastic[^1] goes far beyond just holding your product. It's the first line of defense for the formula you worked so hard to create. From my manufacturing perspective, this is where many brands stumble. They see the package as just a shell, but it's an active component of the product experience.

Product Protection and Stability

Your product needs protection from oxygen, moisture, and UV light. Different plastic[^1]s offer different levels of protection, known as barrier properties[^7]. An unstable formula leads to unhappy customers and wasted inventory. For example, a sensitive Vitamin C serum needs a package that blocks light and air to prevent it from oxidizing and becoming useless.

Formula and Package Compatibility

This is a huge one. Your cosmetic formula can chemically react with the plastic[^1]. Some ingredients, especially essential oils and certain solvents, can cause the plastic[^1] to warp, crack, or leach chemicals into your product. I once worked with a brand whose face cream caused their chosen jars to become brittle and crack over time. They skipped compatibility testing[^8], and it cost them a whole production run.

| Consideration | Bad Choice Example | Good Choice Example |

|---|---|---|

| Formula | A citrus oil cream in a PET jar. | A citrus oil cream in a PP jar. |

| Protection | A light-sensitive serum in a clear jar. | The same serum in an opaque or UV-coated bottle. |

| User Feel | A luxury cream in a flimsy, thin-walled jar. | The same cream in a heavy-walled SAN jar. |

What Are the Most Common Plastic Materials Used in Cosmetics?

The world of plastic[^1]s seems complex, with endless acronyms. Choosing blindly is a huge risk for your product. Let's simplify the most common options you will encounter.

The most common cosmetic plastic[^1]s are PET, known for its clarity and strength; PP, for its heat resistance and durability[^3]; HDPE, for its robustness in bottles; and SAN/AS, for its glass-like look. Each has unique properties suited for different applications.

Understanding these materials is your first step toward making an informed decision. You don't need to be a chemical engineer, but knowing the basics will help you have a much more productive conversation with your packaging supplier[^9]. Think of these as the primary tools in your packaging toolbox. Each one has a specific job to do. Over the years, I've seen each of these materials used brilliantly—and poorly. The difference was always in whether the brand understood the material's core strengths and weaknesses.

A Quick Guide to Common Plastics

| Material | Full Name | Key Properties | Common Cosmetic Uses |

|---|---|---|---|

| PET / PETG | Polyethylene Terephthalate | Glass-like clarity, good impact resistance, good barrier. | Bottles for lotions, serums, toners. Jars for creams. |

| PP | Polypropylene | High heat resistance, durable, good chemical resistance[^2]. | Jars, caps, airless pumps, tottles. |

| HDPE | High-Density Polyethylene | Stiff, strong, good moisture barrier, often opaque. | Bottles for shampoo, conditioner, body wash. |

| LDPE | Low-Density Polyethylene | Flexible, soft, squeezable. | Squeeze tubes for cleansers, lotions. |

| SAN / AS | Styrene Acrylonitrile | High clarity, rigid, brittle, glass-like look. | Luxury jars, compacts, caps. |

How Do You Match a Plastic Material with Your Specific Product?

You have a great formula but no idea what kind of container to put it in. A mismatch can cause the formula to separate, degrade, or even leak out.

Match plastic[^1]s to your product by first analyzing your formula's ingredients. Oil-based products need materials like PP that resist oils, while water-based formulas work well with PET. Also, consider viscosity for dispensing and required barrier properties[^7] for active ingredients.

This is the most critical step, and it's all about compatibility. I can't stress this enough: your product's formula dictates the packaging, not the other way around. You have to think like a detective and investigate every ingredient in your product to find the right home for it. A beautiful package that destroys the product inside is a complete failure.

The Matching Process

-

Analyze Your Formula's Base: Is your product primarily water-based, oil-based, or alcohol-based?

- Oil-based formulas can be aggressive towards certain plastic[^1]s like PET. Polypropylene (PP) is often a safer choice because of its excellent chemical resistance[^2].

- Alcohol-based formulas, like perfumes or some toners, can cause stress cracking in materials like SAN. Testing is essential here.

- Water-based formulas are generally compatible with a wide range of plastic[^1]s, making PET a popular and cost-effective option.

-

Consider the Application: How will the customer use the product?

- A thick cream needs a wide-mouth jar (PP or SAN).

- A low-viscosity serum needs a bottle with a dropper or pump (PET).

- A face wash needs a squeezable tube (LDPE) or a pump bottle (HDPE or PET).

-

Test, Test, and Test Again: The only way to be 100% sure is to conduct a compatibility test. Fill a sample of the package with your final formula. Then, let it sit for at least 4-8 weeks at different temperatures to see if there are any changes to the product or the package.

Appearance vs. Performance: What Do Brands Often Overlook?

A beautiful package design is your top priority. But if that package fails in transit or on the shelf, its beautiful look is completely worthless. You must balance aesthetics[^10] with function.

Brands often overlook how a plastic[^1]'s performance is affected by the entire supply chain[^11]. They choose a material for its shelf appeal but forget to test its durability[^3] during shipping, its reaction to heat in a warehouse, or its compatibility with the filling process.

This is the classic mistake I see all the time. A marketing team designs a stunning package that looks like heavy glass. They choose a material like SAN for its clarity and premium feel. But they don't consider what happens before it gets to the shelf. The package might get dropped during shipping, and SAN can be brittle and crack easily. Or, it might be filled at a high temperature that warps the material. Performance must be considered from the very beginning of the process, not as an afterthought. A product that looks great but arrives damaged is a guaranteed return and a bad review.

The Full Lifecycle of a Package

| Stage | Appearance-First Risk | Performance-First Benefit |

|---|---|---|

| Filling | Material warps from heat or reacts with the formula. | Material is stable and selected for formula compatibility. |

| Shipping | Package cracks from impact or leaks due to pressure changes. | Durable material withstands drops and pressure changes. |

| Storage | Product degrades due to poor barrier properties[^7] in a hot warehouse. | High-barrier material protects formula integrity. |

| Consumer Use | Cap breaks or jar shatters when dropped in the bathroom. | Package is user-friendly, reliable, and safe. |

How Can You Approach Sustainability in Plastic Cosmetic Packaging?

You want to be eco-friendly but feel overwhelmed by all the options. Greenwashing claims can backfire if they are not genuine. The key is to focus on real, impactful choices.

Approach sustainability[^12] by prioritizing materials that are widely recyclable, like PET and HDPE. Consider using Post-Consumer Recycled (PCR)[^13] content, designing for mono-material packaging[^14], and exploring options like refillable systems[^15]. The goal is to reduce virgin plastic[^1] and improve end-of-life outcomes.

Sustainability is no longer a "nice-to-have"; it's a core expectation from consumers. But navigating this space is tricky. My advice is to focus on practical steps that make a real difference, rather than chasing trendy but unproven "bioplastic[^1]s" that can contaminate recycling streams. Honesty and transparency[^16] are your best assets here.

Practical Steps to Sustainability

- Choose Recyclable Materials: Stick with plastic[^1]s that have a clear and established recycling stream. PET (#1) and HDPE (#2) are the most widely recycled plastic[^1]s globally. Avoid materials that are technically recyclable but rarely accepted by local facilities.

- Incorporate PCR Content: Using Post-Consumer Recycled (PCR)[^13] plastic[^1] means you are creating a market for recycled materials and reducing the need for new, virgin plastic[^1]. You can start with 30% PCR and go up from there. Be aware it can affect the color of the final package, so transparency[^16] with your customers is key.

- Design for Recyclability: A package made from a single material (a "mono-material" package) is much easier to recycle than one with mixed materials. For example, a PET bottle with a PET cap is better than a PET bottle with a metal cap. Keep it simple.

- Consider Refills: A great way to reduce single-use packaging is to offer a durable primary container and sell refills in simpler, lower-impact packaging.

What Are the Most Common Mistakes Brands Make When Choosing Plastics?

You feel confident in your packaging choice. But a simple oversight could derail your entire product launch. You can avoid major problems by learning from the common mistakes I've seen.

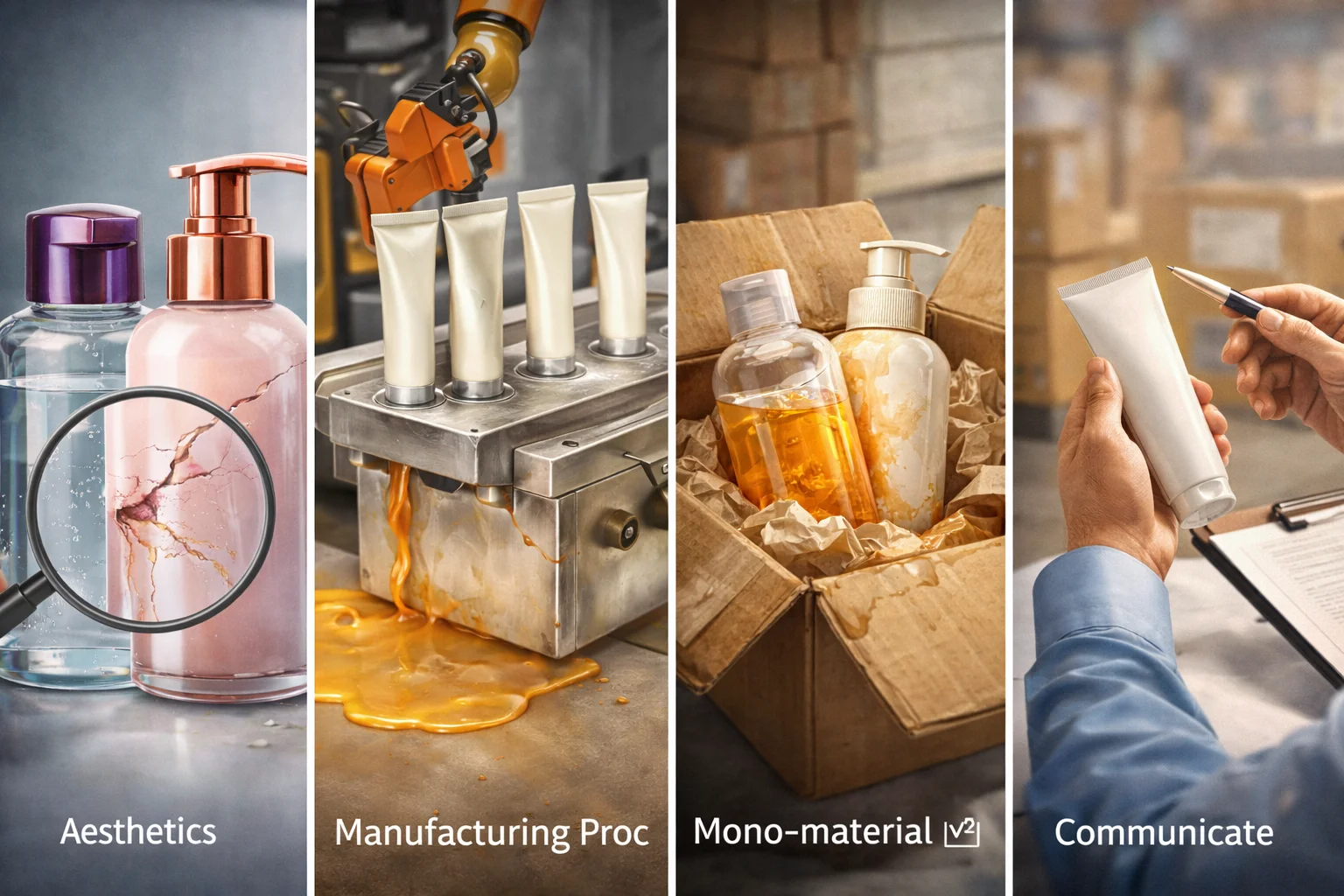

The most common mistake is choosing a plastic[^1] based on aesthetics[^10] alone, without compatibility testing[^8]. Other errors include ignoring the manufacturing process[^17], not considering shipping conditions[^18], and failing to communicate clearly with packaging supplier[^9]s about the product formula[^19].

I could write a book about the preventable problems I've helped brands fix. Almost all of them boil down to a few fundamental oversights made early in the development process. These mistakes are expensive, not just in terms of money, but also in lost time and brand reputation. Let's make sure you don't repeat them.

Top 3 Mistakes to Avoid

- Skipping or Rushing Compatibility Testing: This is the number one error. I remember a brand with a fantastic new face cream that contained citrus oils. They chose a beautiful, clear PET jar. On the shelf, it looked amazing. But after a few months, customers complained that the jars were cracking. The citrus oils were slowly attacking the PET. A simple 8-week compatibility test would have caught this, and they would have chosen a PP jar instead.

- Ignoring the Supply Chain: How will your product be shipped? By air, sea, or ground? Air freight involves significant pressure changes that can cause poorly sealed packages to leak. A truck trailer in Arizona can reach extreme temperatures, which could warp certain plastic[^1]s or degrade your product. You have to test for these real-world conditions.

- Hiding Your Formula from Your Supplier: Some brands are secretive about their formulas, but you must be transparent with your packaging partner. We need to know if you are using aggressive ingredients like high levels of alcohol, essential oils, or acids. A good supplier isn't trying to steal your formula; we're trying to prevent a packaging failure.

So, How Do You Choose the Right Plastic Packaging Solution?

All of this information can seem daunting. You might be worried about making the wrong call for your brand. The best way forward is to follow a clear, step-by-step process.

To choose the right solution, start with your product formula[^19] and user needs. Then, consult an experienced packaging supplier[^9], request samples of different materials, and conduct thorough compatibility and transit testing. This systematic approach minimizes risk and ensures a successful launch.

Making the right choice isn't about luck; it's about having a good process. Don't just pick something from a catalog because it looks nice. By following a structured approach, you turn a complex decision into a series of manageable steps. This is how professional brands ensure their packaging works every single time.

Your Action Plan for Success

| Step | Key Question(s) | Action Item |

|---|---|---|

| 1. Define | What is my formula? Who is my customer? What is my budget? How will it be dispensed? | Create a detailed product brief that answers these questions before you even look at packaging options. |

| 2. Consult | What materials does my supplier recommend for this formula? What are the pros and cons? | Share your product brief and full ingredient list with a trusted packaging expert. Listen to their advice. |

| 3. Sample | Can I get samples of the recommended materials and components? | Get physical samples. Feel them. Use them. See how they look with your branding mockups. |

| 4. Test | Is the package compatible with my formula? Can it survive shipping and handling? | Conduct full compatibility and transit testing. Fill the samples and simulate real-world conditions. Do not skip this. |

| 5. Finalize | Does the final choice meet my brand's needs for performance, appearance, and cost? | Make your final decision based on data and testing, not just on your gut feeling. |

Conclusion

Choosing the right plastic is about balancing looks with performance. Smart, early decisions protect your product, your brand, and your budget. Test everything before you commit to production.

[^1]: Understanding the types of plastic can help you make informed choices for your products.

[^2]: Learn how chemical resistance affects product stability and customer satisfaction.

[^3]: Explore how durability impacts the overall user experience and brand reputation.

[^4]: Discover the crucial role packaging plays in maintaining the quality of your products.

[^5]: Safety is paramount; find out how to ensure your packaging is safe for consumers.

[^6]: Understanding shelf life can help you choose the right materials for longevity.

[^7]: Learn about barrier properties and how they protect your product from external factors.

[^8]: Compatibility testing is essential; find out how it can save you from costly mistakes.

[^9]: Choosing the right supplier is crucial; find out what to consider in your selection.

[^10]: Understand the balance between aesthetics and functionality in packaging design.

[^11]: Learn how supply chain considerations can impact your packaging decisions.

[^12]: Explore sustainable options that can enhance your brand's reputation and appeal.

[^13]: Learn how using PCR can reduce environmental impact and promote recycling.

[^14]: Discover the advantages of mono-material packaging for recycling and sustainability.

[^15]: Refillable systems can reduce waste; find out how they can benefit your brand.

[^16]: Transparency can prevent packaging failures; find out how to communicate effectively.

[^17]: Explore how manufacturing choices can influence the performance of your packaging.

[^18]: Shipping conditions can affect product integrity; learn how to prepare for them.

[^19]: Understanding your formula is key to selecting the right packaging materials.