Lotion pumps are essential tools in our daily skincare routine, yet many of us don’t fully understand how they work. You may have wondered, "How does this tiny device deliver the perfect amount of product every time?" In this post, we’ll explore the anatomy of a lotion pump and the mechanics behind its function.

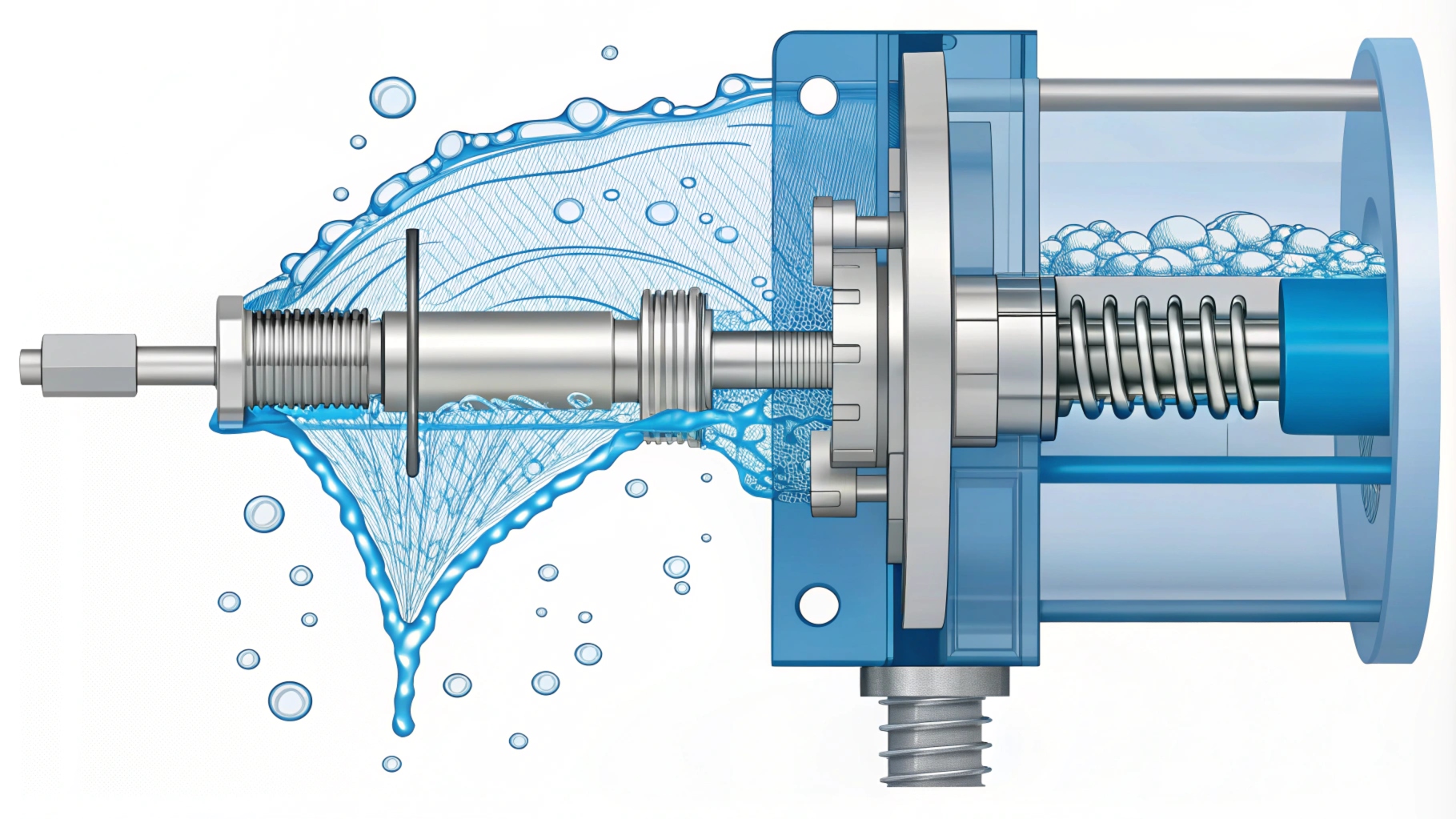

A lotion pump consists of several key components: a nozzle1, a spring2, a tube, and a piston. When you press down on the pump, it activates the spring and piston, drawing the liquid from the bottle and delivering it through the nozzle.

Understanding how a lotion pump functions can help you better appreciate this everyday item. Now, let’s take a deeper dive into the mechanics behind cosmetic pumps.

[Table of contents]

How do cosmetic pumps work?

Cosmetic pumps, like lotion pumps, are designed to dispense a controlled amount of product. But how exactly do they achieve this?

Cosmetic pumps use a combination of spring-loaded mechanisms and pressure to draw liquid from the container and send it through a nozzle. When you press down on the pump, it creates a vacuum that pulls the product upwards and out.

Cosmetic pumps are cleverly engineered with precision. The key component, a piston3, moves inside a cylinder when the pump is pressed. This creates negative pressure, causing the liquid to move from the bottle. The nozzle at the end controls the amount of product dispensed.

Key Components of Cosmetic Pumps

| Component | Function |

|---|---|

| Piston | Creates the pressure that pushes the liquid out |

| Spring | Provides the force to return the piston after use |

| Nozzle | Controls the flow and amount of product dispensed |

| Tube | Connects the pump to the bottle and carries the product |

How does a lotion pump work?

You’ve probably noticed how efficiently a lotion pump dispenses just the right amount of product. But how exactly does it achieve this?

A lotion pump works by using a combination of spring tension and air pressure to draw liquid from the bottle and through the nozzle. When you push down, the mechanism opens a valve4 and releases the product.

The valve inside the pump controls how much lotion is dispensed with each press. The pump is designed to dispense only a small amount at a time, allowing for controlled usage.

The piston inside a lotion pump moves in and out when pressed. The spring pushes it back into place, ensuring the pump is ready for the next use. This simple yet effective design ensures consistency and prevents spillage or waste.

How a Lotion Pump Prevents Spillage

A lotion pump is designed to prevent excess product from being dispensed. The small, controlled valve inside the nozzle ensures that the pump doesn’t release too much lotion at once. This makes it easy to regulate the amount of product used, preventing waste.

How to make a lotion pump work?

Understanding the basic functionality of a lotion pump is one thing, but how can you make it work smoothly every time?

To ensure your lotion pump works effectively, always check that the nozzle and tube are free from blockages. If the pump stops dispensing, try priming it by pressing the pump a few times to remove any air.

If the pump mechanism becomes stiff, it could be because of product buildup or air trapped in the system. Cleaning the pump periodically can help avoid these issues.

Sometimes, a lotion pump may stop dispensing due to clogs or air pressure issues. If the product is too thick, you can dilute it slightly to ensure smooth flow. Additionally, consider the length of the tube—if it doesn’t reach the bottom of the bottle, the pump may not be able to draw the liquid properly.

Troubleshooting a Lotion Pump

| Issue | Solution |

|---|---|

| No product dispensed | Press the pump multiple times to remove air bubbles |

| Pump is stiff | Clean the pump or dilute the lotion slightly |

| Liquid not flowing | Check if the tube is disconnected or clogged |

How does a liquid dispenser work?

Liquid dispensers, like lotion pumps, are all about pressure and flow control. They are built to dispense liquids in a controlled manner, whether it’s lotion, soap, or even shampoo.

A liquid dispenser works by creating pressure inside a chamber, which forces liquid through a valve and out the nozzle. This system ensures that only the right amount of liquid is dispensed each time.

The dispenser uses a similar mechanism to lotion pumps, with the added complexity of controlling the liquid’s viscosity5, ensuring smooth flow.

In a liquid dispenser, the type of liquid being dispensed matters a great deal. Thicker liquids may require more force to push through the valve, whereas thinner liquids will flow more easily. Some dispensers have adjustable settings to cater to different viscosities, providing a more versatile product.

Types of Liquid Dispensers

| Type | Ideal For |

|---|---|

| Trigger Sprayers | Cleaning products and air fresheners |

| Push-button Pumps | Lotions and shampoos |

| Squeeze Bottles | Hand sanitizers and condiments |

Conclusion

In this post, we’ve learned about the inner workings of a lotion pump and similar liquid dispensers. These small but ingenious devices use pressure and valve mechanisms to dispense liquid in a controlled manner, preventing waste and ensuring ease of use.

Footnotes

-

This article explains the function of the nozzle, which helps control the dispensing of the product. ↩

-

The spring’s role in pumps is crucial for returning the piston to its original position after use, ensuring efficiency. ↩

-

The piston is the core element in the pump mechanism, responsible for creating the necessary pressure to push out the liquid. ↩

-

The valve inside the pump controls the amount of product dispensed, preventing waste and ensuring precision. ↩

-

Viscosity impacts how easily a liquid flows through the dispenser; thicker liquids may need adjustments in the pump mechanism. ↩