Lotion pumps might look simple, but choosing the right materials can make or break a skincare product. It's about performance, not just appearance.

Lotion pumps are made from materials like PP, PE, stainless steel, and silicone1—each playing a unique role in the pump’s function and feel.

I remember when my client Avin asked me what materials we use for lotion pumps. That question led to a deeper conversation about product quality, leakage, and how one tiny part can impact a brand’s image.

What Are the Materials and Components That Make Up a Lotion Pump?

Not all pumps are created equal—every internal piece affects the way it works.

Most lotion pumps contain five core components: actuator, closure, spring, gasket, and dip tube2—made from plastic, metal, and rubber.

The Core Parts of a Lotion Pump

| Component | Material | Purpose |

|---|---|---|

| Actuator | PP or ABS | The press-down part users touch |

| Spring | Stainless steel | Brings the actuator back up |

| Gasket | Rubber or silicone | Seals the pump to prevent leakage |

| Closure | PP or PE | Screws onto the bottle |

| Dip Tube | PE | Pulls the product from the bottom |

When clients are unsure about quality, I always walk them through this structure. It helps them make informed decisions, especially when comparing suppliers.

How Do Well-Designed Lotion Pumps Support Contract Manufacturing?

If you're in contract manufacturing like I often help with, your packaging is your brand’s first impression.

A good pump3 can reduce customer complaints, prevent leaks in shipping, and give your product a premium feel.

Why Design and Material Matter

- A smooth actuator improves user experience

- Strong seals mean less leaking during transit

- Durable springs ensure consistency over time

- Higher-quality plastic avoids yellowing and warping

In contract manufacturing, I always recommend testing samples from multiple suppliers. It avoids unexpected issues before mass production.

What Packaging Features Do Private Label Skincare Brands Need?

Brand owners often ask me what makes a lotion pump look “premium” or “retail ready.”

Private label skincare packaging4 should reflect your brand, deliver consistent quality, and make a strong shelf impression.

Customization Options I Recommend

- Color-matching pump and bottle for brand consistency

- Metallic accents like silver collars or gold tips

- Hot-stamped logos for a high-end touch

- Pump dosage control (like 0.2ml or 0.5ml)

- Matte finishes for a minimalist, luxe aesthetic

These small upgrades help smaller brands compete with giants in crowded markets.

Why Does the Material in Plastic Lotion Pumps Matter?

Cheaper pumps aren’t always cheaper in the long run—trust me, I’ve seen it go wrong.

The material5 affects chemical resistance, user safety, recyclability, and how long the pump lasts.

Comparing Material Options

| Material | Key Benefit | Ideal Use |

|---|---|---|

| PP | Chemical resistance | Lotions and creams |

| ABS | High gloss, premium feel | Serums or luxury lines |

| PETG | Transparency and strength | Shower gels or oils |

I always suggest checking compatibility with your formula. Some oils or actives can break down plastic over time if the wrong one is used.

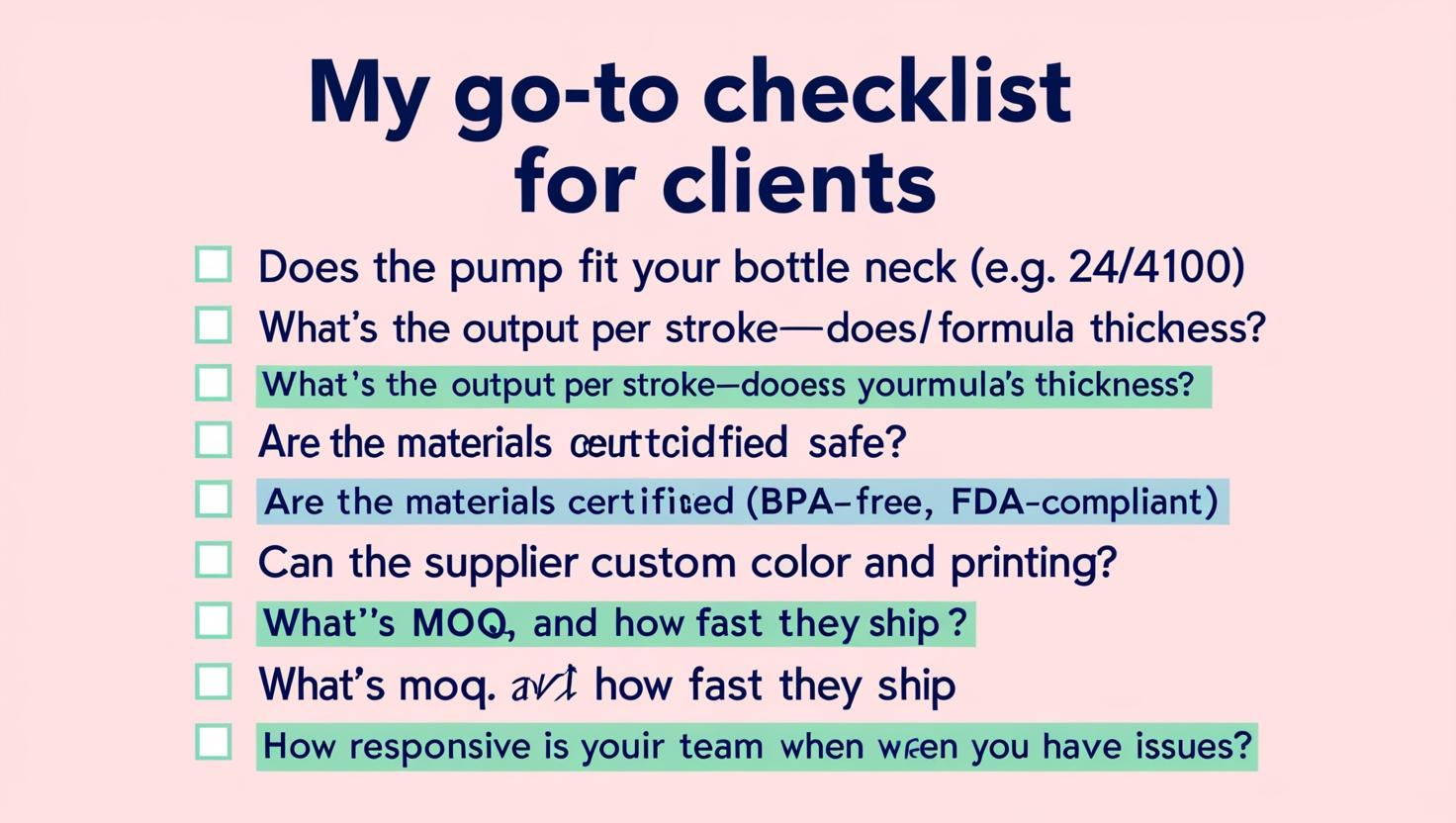

What Should You Consider Before Purchasing Lotion Pumps?

Even if a pump looks good in photos, that’s not enough.

Before you order, test for fit, dosage, chemical resistance, MOQ, and supplier response time.

My Go-To Checklist for Clients

- Does the pump fit your bottle neck (e.g. 24/410)?

- What’s the output per stroke—does it match your formula’s thickness?

- Are the materials certified safe (BPA-free, FDA-compliant)?

- Can the supplier customize color and printing?

- What's the MOQ, and how fast can they ship?

- How responsive is their team when you have issues?

Avin once switched to a new supplier without checking some of these, and the pumps didn’t fit his bottles—delaying his launch by a month. Lesson learned.

Conclusion

Behind every pump is a set of smart material choices that affect your cost, quality, and customer experience.

-

Understand why specific materials like PP and stainless steel are common in pump manufacturing. ↩

-

Learn how each component works so you can make better purchasing decisions. ↩

-

Discover how better pumps reduce product failure, returns, and complaints. ↩

-

Explore design and customization options that help private label brands stand out. ↩

-

Learn how plastic selection impacts formula compatibility, sustainability, and safety. ↩